With the implementation of Order ICT/155/2020, dated 7 February, which regulates the metrological control of certain measuring instruments in service in Spain, we previously explained how it impacted the water meter network. In this post, we will provide a useful summary of the law's implications for gas meters and converters.

This regulation aims to establish a rigorous legal framework to ensure precise and reliable measurements. The ultimate goal is to protect consumers while fostering transparency in the gas market, aligning Spanish regulations with European directives and standardising practices across the industry.

|

Gas meter: An instrument designed to measure, record, and display the amount of combustible gas (volume or mass) that has passed through it. Conversion device: A device installed in a gas meter that automatically converts the measured quantity under measurement conditions to a quantity under standard conditions. |

Conformity Assessment of Measuring Instruments

Before measuring instruments can be marketed, the new law emphasises the conformity assessment required for the selling and commissioning of gas meters, as outlined in Annex VIII of Real Decreto 244/2016 of 3 June. This assessment must comply with the essential requirements that measuring instruments must meet, including CE marking.

The evaluation ensures that gas meters are accurate and reliable before being used commercially, meeting metrological regulations, specifically:

- it must be suitable for the specific installation conditions,

- it must meet the flow rate demands and temperature and pressure requirements as set out in the Real Decreto,

- it must be designed for the range of gases (family or group) in the destination country (the manufacturer may be based elsewhere) and the maximum operating pressure,

- it must have appropriate metrological quality.

(for more details, refer to Annex IX of the Real Decreto)

Once the meters are in service, Order ICT/155/2020 regulates their lifespan and metrological control, which may include verification after repair or modification and/or periodic verification. The measuring instrument must be properly sealed by the person/entity conducting the verification, following procedures regulated by the administrative body responsible for verification, as established by the Real Decreto 889/2006 of 21 July.

Updates in Order ICT/155/2020

The law distinguishes between two types of devices based on the volume of gas measured.

For the first type, the law defines a lifespan and excludes these devices from periodic verification, meaning all meters that have exceeded or are close to exceeding their lifespan must be replaced. For the second type, there is no obsolescence requirement, but instead, they must undergo periodic verification.

The reason behind this measure, particularly for smaller meters commonly used in millions of households, is that the cost of verifying these meters equals or even exceeds the cost of replacing them.

1/ For meters with a maximum flow rate ≤ 25 m³/h

The regulation establishes a lifecycle for gas meters with a maximum flow rate of 25 m³/h (or an equivalent mass flow rate), as well as the associated converters.

According to the new law:

- lifespan is set at 20 years, extendable in increments of 5 year,

- they are not subject to periodic verification,

- repairs or modifications are prohibited.

In terms of deadlines, the maximum period for applying the law—i.e., for replacing meters that have exceeded or will soon exceed their lifespan—is 8 years from its enforcement date (24/10/2020), although with varying specific timelines.

The deadlines are as follows:

|

Gas Meters and Volumetric Conversion Devices (maximum flow rate equal to or less than 25 m³/h) |

Lifespan (years) |

Deadline for Renewal Request |

Final Renewal Deadline |

| Replacement of 30% of the network | 20 (*) | 24/09/2023 | 24/10/2023 |

| Replacement of 60% of the network | 20 (*) | 24/09/2025 | 24/10/2025 |

|

Replacement of 100% of the network (up to 2% of meters may remain unreplaced due to reasons beyond the distributor's control) |

20 (*) | 24/09/2028 | 24/10/2028 |

(*) The lifespan may be extended in successive five-year periods if the distribution company demonstrates compliance with the requirements set out in the order through verification conducted by an authorised metrological verification body.

This schedule will be adjusted to account for future regulations regarding the implementation of smart meters.

2/ For Meters > 25 m³/h ≤ 250 m³/h

Order ICT/155/2020 also sets guidelines for gas meters with a flow rate exceeding 25 m³/h and up to 250 m³/h (or equivalent mass flow rate), as well as associated converters subject to the State’s metrological control during marketing and commissioning, intended for residential, commercial, or light industrial use.

For meters within this volume range, there is no replacement plan. Instead, they are subject to verification after repair or modification, as well as successive periodic verifications.

The meter owner, following intervention by the repairer, must arrange metrological verification with an authorised metrological verification body or the competent public administration acting as the body. The latter will have 1 month to carry out the verification. The measuring instrument cannot be used until it passes verification, which must be certified within 5 days of the verification.

The verification schedule depends on the type of meter based on the measurement method:

|

Gas Meters and Volumetric Conversion Devices (exceeding 25 m³/h and up to 250 m³/h) Type: |

Initial Verification Period (years) from commissioning) (**) |

Subsequent Verification Periods (years) |

| Diaphragm | 10 | 5 |

| Rotary displacement | 6 | 3 |

| Turbine | 4 | 2 |

| Converter | 4 | 2 |

(**) The initial verification deadlines, as listed in the table, are calculated from the commissioning date, which is defined as the meter’s first use by the end user.

Who Is Responsible for Verifying Gas Meter Compliance?

The ultimate responsibility for verification lies with the meter owner, who is typically the consumer. However, in most cases, the verification or replacement is handled—under delegation from the owner—by the gas supply or distribution company.

Responsibilities by Meter Type:

a) Meters with a maximum flow rate ≤ 25 m³/h

a. Unit Verification: The instrument owner, as the ultimate responsible party, must request verification from a qualified company, usually the gas distribution company itself. The owner must sign a written agreement with the gas company to confirm delegation. If delegation is not provided, the company is obliged to inform the Spanish administration.

b. Statistical Sampling Verification: In this case, the gas distribution company always performs and assumes responsibility for the verification.

b) Meters with a flow rate > 25 m³/h ≤ 250 m³/h

The owners of these meters and their associated converters, if applicable, are required to request periodic verification by unit. If the owner is the end consumer, they must sign a written agreement with the gas company to delegate the relevant tasks, operations, and arrangements for these verifications. Should the owner decline to delegate these responsibilities, the gas distribution company is required to notify the Spanish administration.

|

Regardless of who is responsible, only an authorised company or installer is permitted to carry out any work on the installation.

|

Challenges in Implementing the Replacement of the Gas Meter Network

In Spain, the gas meter fleet includes over 5 million units that are more than 20 years old, representing approximately 70% of the total.

Managing and deploying resources to modernise the country's gas meters will undoubtedly be a monumental task. One of the challenges faced by gas distribution companies is adapting new meters to the gas supply network or to the Common Receiving Installation in shared residential buildings, which may have features incompatible with the meters. The meters themselves often have varying lengths between axes and must connect to the specific receiving installation with its own unique characteristics and dimensions.

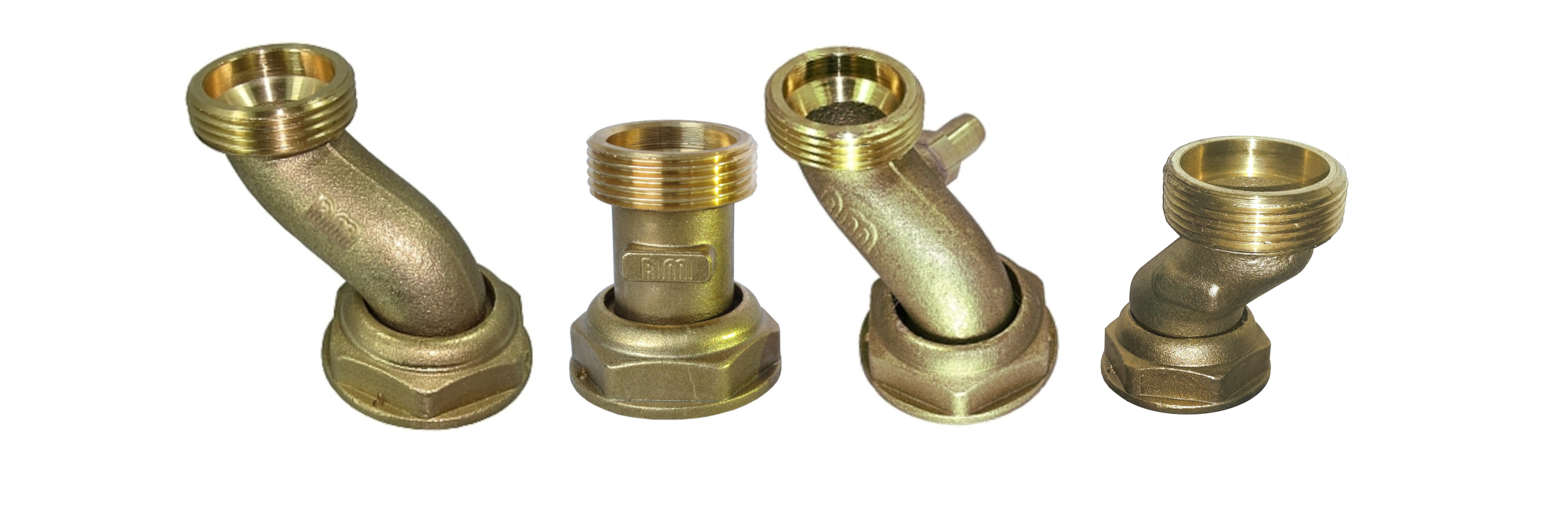

At rmmcia, we offer brass connectors S-shaped (also known as eccentric), that address different widths and ensure compatibility between the meter and the installation. Additionally, custom-made fittings can provide solutions for unforeseen situations that installers may encounter across the country, depending on the type of meter and connection point selected.

Our eccentric fitting is available in multiple sizes, ranging from 7/8” to 1.1/4”.

All gas fittings are equipped with a sealable hole, a mandatory requirement following repairs or modifications, as well as subsequent verifications by the authorised entity.

Below are some examples:

STRAIGHT OR ECCENTRIC MALE-FEMALE ADAPTER FITTINGS WITH SWIWEL NUT, WITH OR WITHOUT PRESSURE INTAKE POINT.

Check with us should you have any specific need and you don't find your accessory, or do you wish a customized fitting.